Capabilities

Zinc Die Casting

Our Die Casting capabilities include Conventional and Four Slide Techmire™ die casting machines. We can produce parts up to 9 ounces in weight. Computer controlled process systems allow us to meet close tolerance requirements.

Stamping

Our presses range in size from 24 to 150 ton capacity. The speed of our presses varies from 20 to 450 strokes per minute. We inventory a wide range of steel and brass coil material to satisfy the demands of our customers who give us short lead times. We also have many nearby quality sources that can supply us with material at short notice.

ETCI builds stamping dies for the outside as well as for in house production runs. Many parts produced by ETCI are run in master dies with interchangeable cutting inserts. This means we can reduce the initial cost of tooling to the customer because the dies produce many different parts of many thicknesses and contours. ETCI has a no cost to the customer policy on maintaining tooling it builds and runs.

|

|

|

|

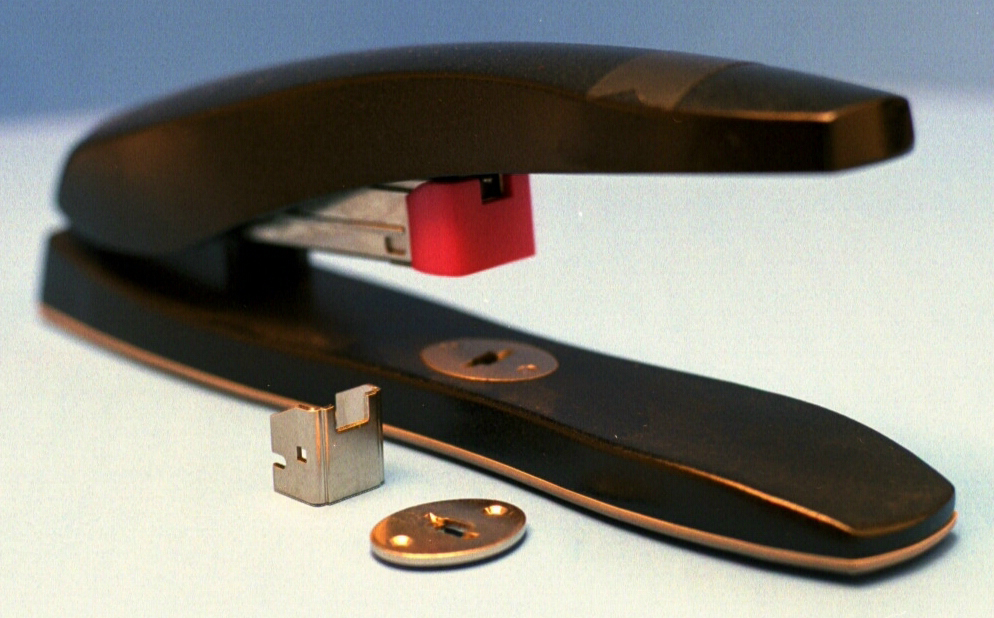

| Stampings that include a stapler anvil and staple channel guide from a stapler that can staple from 2-60 sheets of paper |

|

Metal stampings of steel cams, steel spring clips, steel washers, brass keys and steel keys |

|

Tooling

Our fully equipped Tool Room can handle virtually all of our production needs in house allowing us to quickly turn around jobs with a minimum of outsourcing. We design and build tools and machines to customer specifications using our years of experience to cut lead times and lower production costs. Once a tool is finished, we don't consider our job is finished, as our standard practice is to perpetually maintain tooling we build and run in house at no additional cost to our customer.

|